Studying the Moisture Sorption of Polymer Films

Polymer films are thin continuous plastic materials used to create a range of commercial products. They are formulated from almost any type of plastic, including: polyethylene; nylon; and emerging bioplastics. As such, the applications of polymer films are enormously wide-ranging. They are used in the formation of conventional movie film stock, moisture-resistant pharmaceutical packaging, antibacterial food wrappings, and biodegradable shopping bags. Each of these commodities has uniquely specific requirements, so it is important to comprehensively characterize polymer films to establish their commercial capabilities and industrial uses.

Moisture sorption, or water vapor sorption, is one of the most consistently integral measurements for polymer film materials regardless of their eventual application. Mechanical strength and stability are often important metrics for plastics designed to act as volumetric barriers or to bear weight, while transparency is crucial for the development of photographic film strips. However, each of these applications and properties can be detrimentally impacted by a polymer’s moisture sorption properties. High moisture contents may upset a polymer film’s chemical stability and result in the accumulation of mold, while low moisture contents can reduce its physical stability and result in product embrittlement.

Moisture Sorption Measurements of Polymer Films

Moisture diffusion, or hygroscopic swelling, is a method of determining a polymer’s moisture sorption resulting from mass changes under varying atmospheric conditions. These characteristics are determined through dynamic vapor sorption (DVS) analysis, a methodology that involves studying mass changes of samples whilst altering parameters such as humidity, vapor flow rates, and temperature to determine a material’s moisture sorption characteristics.

The response test is a method used to directly study the kinetics of moisture sorption in a material, as the applied humidity and hence moisture concentration within the sample is increased from one value to another. This response method is more complex when applied to polymer films, as moisture sorption of plastics is affected by a multitude of factors. Moisture sorption could cause the polymer to unevenly swell, causing water molecules to bond with polymer chains and become immobile. This can detrimentally affect the diffusion rate as dependent upon concentration.

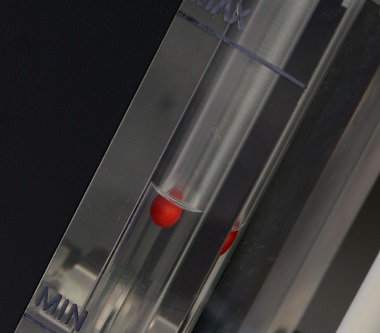

However, the IGAsorp DVS analyzer successfully uses this technique to determine precise equilibrium curves and diffusion coefficients for thin polymer films. Mass changes from 0.1 μg are recorded by a sensitive microbalance, which is independently thermostatted to ensure long term stability and eliminate anomalous thermal coefficients. The relative humidity (RH) can be regulated between 0 – 98%, and simultaneously the sample’s temperature can be regulated from 5 – 85°C, or dried at temperatures of up to 350°C.

This apparatus has been used to measure the moisture sorption of polymer films for food and pharmaceutical applications, providing valuable data regarding the physical properties of polymer films under varying atmospheric conditions.

Moisture Sorption Measurements from Hiden Isochema

Hiden Isochema are experts in the field of gravimetric analysis and moisture sorption measurements, providing dedicated instrumentation for a broad range of practical applications. If you would like any more information about our IGAsorp DVS analyzer, or other products, please do not hesitate to contact us.