Advanced gas sorption analyzer, with next generation microbalance design for high pressure & corrosive capability

- Widest controllable pressure range of any gravimetric sorption analyzer: active pressure regulation over 7 orders of magnitude

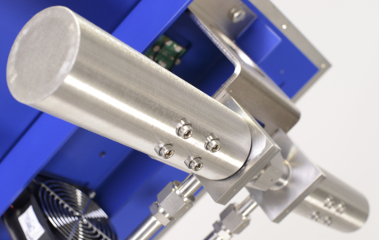

- Unique Exosensing Technology for operation with aggressive species

- Optimized performance for sample sizes from 1 mg to 5 g

The XEMIS series are high accuracy gravimetric sorption analyzers operating to 200 bar. Changes in sample mass are measured as a function of applied temperature and pressure to determine isotherms, isobars and sorption kinetics. Designed for operation with a full range of gas and vapor species including corrosives and flammables, the XEMIS series features active pressure regulation from 10-2 mbar: a controllable pressure range covering 7 orders of magnitude.

The XEMIS series offers reproducible, high resolution, high accuracy measurements even with small sample sizes or small uptakes, and performance unrivalled in a high pressure sorption analyzer.

- Isotherm, isobar and high pressure TGA measurements in a single automated analyzer

- Compatible with flammable, corrosive and toxic gases and vapors

- Symmetric geometry, with ultra-low total system buoyancy for high accuracy measurements at high pressures

- Measurements at temperatures from 77 K to 500 °C

- Fast and accurate analysis of equilibria and kinetics using the IGA method

- Full automation and advanced programmability

Hiden Isochema’s unique IGA method is applied independently to every step in a gravimetric sorption measurement. At each step, the pressure and temperature are actively regulated, with resultant changes in sample weight continuously recorded.

The kinetic weight data is analyzed in real-time, and the trend toward equilibrium is predicted and displayed on screen. Equilibration criteria are applied to objectively determine the period allowed before the measurement moves on to the next pressure or temperature value. Each equilibrium point is plotted on an isotherm or isobar, and the full raw data is also recorded.

The IGA method therefore allows consistent analysis with optimum measurement accuracy and faster overall process times.

Typical applications include:

- Carbon capture and storage

- Hydrogen and natural gas storage

- Gas solubility in ionic liquids

- Nanoporous material characterization

- Gas sorption on geological materials

-

Kinetics of hydrogen absorption by palladium at 303 K and 40 mbar

-

Nitrogen, carbon dioxide and sulphur dioxide adsorption isotherms on a MOF across a broad pressure range. Data reproduced with permission from John Wiley and Sons.

-

Methane adsorption by a shale at high temperature and pressure

-

Sulfur dioxide adsorption by a metal organic framework (NOTT-300)

-

Download the latest XEMIS product brochure in pdf format

-

Measuring H2, CH4 and SO2 by Porous Materials

-

First XEMIS data published in Spring 2015

-

Unique features of XEMIS sorption analyzers demonstrated in new publications

High accuracy gravimetric analyzer, for precise characterization of gas sorption equilibria and kinetics

High resolution gas & vapor sorption analyzer, with next generation microbalance design for high pressure & corrosive capability

Get in touch with us today to speak to one of our experts.

Call us on +44 (0) 1925 244678 or click below to contact us.